The first step in the deck planking process was laying out the lines on the subdeck plywood so I could figure out what wood I needed to do the job. I drew in a 2" grid pattern on the sub-deck to ensure that the center planking would be symetrical. Using a batten, I drew in the perimeter cover board lines to follow the carlings aft of the dash and stay a "constant distance off the shear line" forward of the dash. I made the first line drawn on the forward deck (that I liked) the "master" and copied it to the other side. There is a slight difference in distance to the shear line from one side to the other, but not enough to worry about.

The first step in the deck planking process was laying out the lines on the subdeck plywood so I could figure out what wood I needed to do the job. I drew in a 2" grid pattern on the sub-deck to ensure that the center planking would be symetrical. Using a batten, I drew in the perimeter cover board lines to follow the carlings aft of the dash and stay a "constant distance off the shear line" forward of the dash. I made the first line drawn on the forward deck (that I liked) the "master" and copied it to the other side. There is a slight difference in distance to the shear line from one side to the other, but not enough to worry about.

Then a trip to Armstong millworks to buy some African Mohoghany for the deck planking and then learn how to re-saw. The guys at Armstrong suggested that starting with 4/4 stock planed to as thick as possible (about .90") would be the best approach.

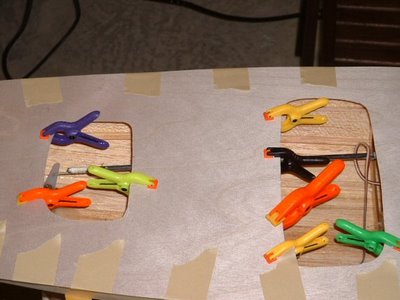

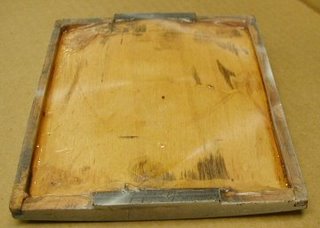

I started with laying out the boards along one side of the boat to determine joint locations to get a 12 long 10" wide board to cover the width and length. Due to the limitations of my shop, the board was cut into the pieces and angles necessary to go around the boat on one side, then each piece re-sawn to create the piece for the opposite side. With a riser kit previously installed on my bandsaw, a new 1/2" wide skip tooth blade, new Olsen "cool blocks" and a 6" tall fence, I started bandsawing the wood for the outer perimeter planking. The piece at the back of the boat was 9 3/4" wide and the re-saw went very, very, slowly, but it worked. Then a few trips through the thickness planer (new blades installed) yielded planks about .34" thick. Using countersunk screws, the first piece was located, beginning at the aft end of the boat and working forward, a joint line established, chop cut on the mitre saw, reinstalled and the next piece cut to fit up against the previous piece.

After the joints were established, the inside line location was transferred from the sub-deck to the underside of the cover boards. In the cockpit and motor opening area, tracing on the underside was straightforward. In other areas the grid pattern was used to re-create the line by tracing the inside edge of the boards onto the grid pattern and measuring to the line intersection at each grid line. Tedious, but it worked. Line was cut on the bandsaw about 1/32" proud and then sanded to the line with a small 1" stationary belt sander. Outer lines were traced, cut, and sanded in a similar manner.

The kingplank down the middle of the boat took a bit of trial and error to find a width that looked "right". I started at 6 1/2" wide, about an inch wider than the perimeter boards in the fore deck area and it seemed too dominant. At 5 1/2" it still seemed too wide, so eventually my aesthetic director concurred with a 4" wide being the "right" width.

The grid pattern helped with cyphering out the width of the longitudinal planks. Eventually settling on 1 7/8" width, and a 3/16" gap. In order to fully utilize the boards I had purchased and not have to go buy more wood, I needed to squeeze four planks from a board width of just under 7 3/4" inch. (Maybe the king plank should have been a bit wider!) This created an opportunity to buy a new tool for the shop - a micro-kerf table saw blade which only cuts a 1/16" wide kerf. After creating a new table saw zero-clearance insert with a splitter, I was all set to cut the planks. The new blade cut like butter and I got all the pieces needed to cover the deck.

The plan at the moment is to stain the perimeter and king planks a darker color to provide greater contrast. Then finish all the planks to seal all the grain and complete the deck using a white pigmented epoxy to fill the gaps.

Then the sheet was taken off the boat and set up in my shop for cutting with a jig saw. I quit for the day at that point to sleep on it before cutting.

Then the sheet was taken off the boat and set up in my shop for cutting with a jig saw. I quit for the day at that point to sleep on it before cutting.

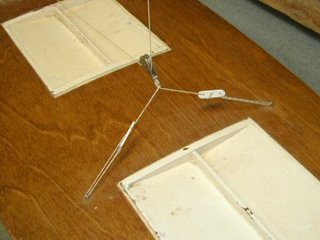

I left overlaps between the front and back pieces to give me some adjustment when finally glued and attached.

I left overlaps between the front and back pieces to give me some adjustment when finally glued and attached.

When we put in a patio I thought I would never have to stain a deck again.... After hand sanding all the deck surfaces with 220 grit, some vacumming, wipe down and room clean-up it was time to mask and stain. A bit of blue tape, plastic and masking paper and I was ready to have at it.

When we put in a patio I thought I would never have to stain a deck again.... After hand sanding all the deck surfaces with 220 grit, some vacumming, wipe down and room clean-up it was time to mask and stain. A bit of blue tape, plastic and masking paper and I was ready to have at it.

Looks pretty cool even if I say so myself.

Looks pretty cool even if I say so myself.